| Weight | 20 kg |

|---|---|

| Dimensions | 12 × 8 × 20 cm |

| Quantity | Single, Matched Pair, Matched Quad |

Product highlights

- Hand-selected and tested

- Gold pins for corrosion resistance and excellent conduction

- A substantial upgrade from standard NOS tubes

- Low noise and microphonics

- Matched quad (4 tubes) or pair (2 tubes) or single tube (1 tube)

- Only 5% of the tubes commissioned for production meet our standards for gain and conductance matching

- 12-month warranty against manufacturing defects

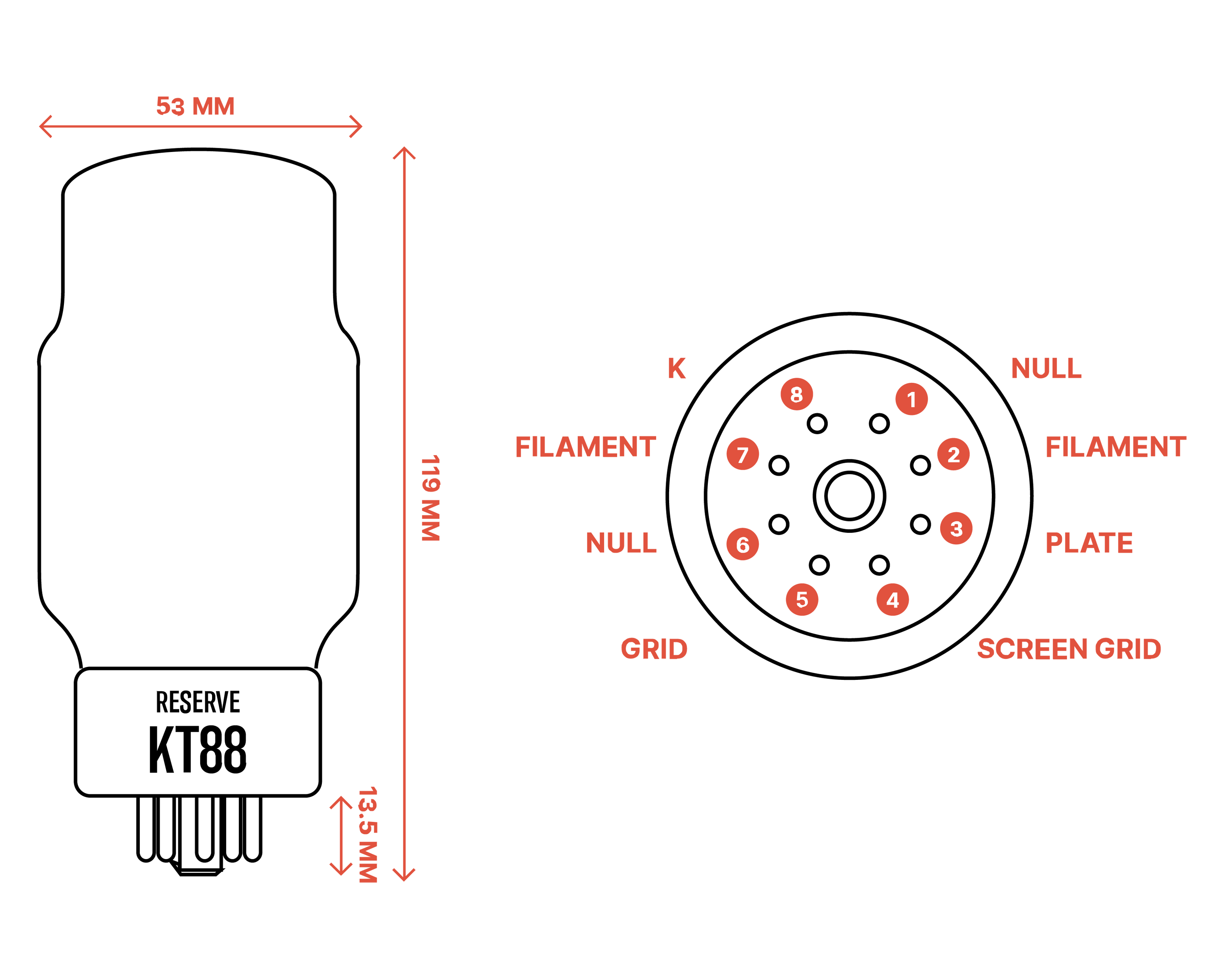

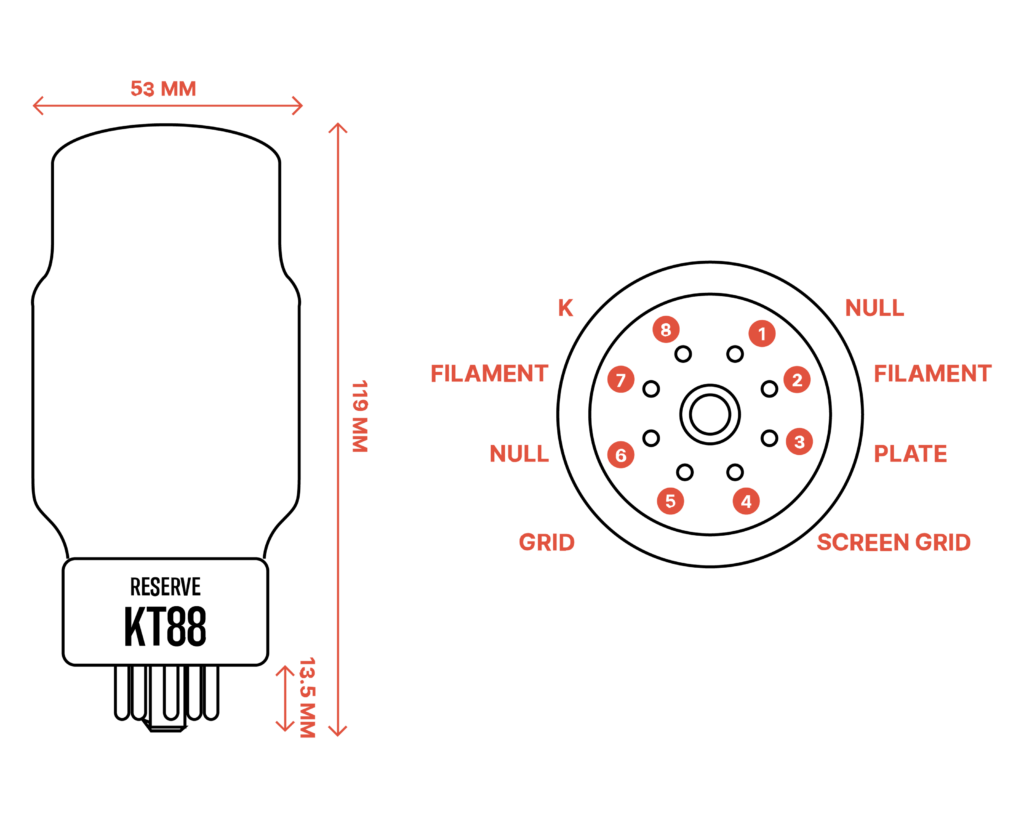

The Ray Tubes KT88 RESERVE Vacuum Tube delivers a profound, lifelike audio experience with smooth vocals, balanced treble, and commanding low-end, tailored specifically for audiophile systems. Each tube undergoes meticulous selection and quality checks, featuring gold pins for enhanced conductivity and durability, making it the supreme upgrade for high-fidelity

applications.

Ray Tubes is revitalizing the vacuum tube market with hand-selected, rigorously-tested tubes, backed by a 1-year warranty that underscores the quality and reliability of their products.

Magic Coating

Some things are better left unseen. You canʼt see inside the RESERVE tube because itʼs coated with something called monocrystalline carbon. This layer keeps the electrons on their toes, cools things down, and blocks out noise. If youʼre into engineering, you might find the science fascinating. For the rest of us, itʼs basically magic. The coating is delicate and tough

to apply, which complicates production. Thatʼs why we only use it for our RESERVE tubes.

Quality Control

Step 1 – Extensive Burn-In

Each tube undergoes a 24 hours burn-in period to stabilize components and identify early signs that might lead to premature failures later on.

Step 2 – Comprehensive Parameter Testing

Tubes are tested against more than a dozen critical parameters like amplification factor and internal resistance.

Step 3 – Individual Measurement Recording

Measurements are logged under each setʼs unique serial number for traceability.

Step 4 – Current Draw Analysis

Industrial-grade instruments measures current draw to ensure fully-accurate matching.

Step 5 – Functional Testing

Tubes are installed in amplifiers to assess real-world performance.

Step 6 – Microphonics Testing

Tubes are subjected to physical stressors to reveal any buzzing or defects.

Step 7 – Expert Listening Sessions

Audio specialists randomly select certain tubes that have passed all previous tests and evaluate the sound quality of tubes.